Introduction

Fuel is a crucial energy source; without it, global operations would come to a standstill. As a developing nation, India depends on various types of fuel. The global shift towards renewable energy has spotlighted solar energy as a key option. Solar energy is clean, abundant, and available throughout the day. Discussions from COP21 highlight that while half the world harnesses solar energy during their daylight hours, the other half does so during their own daylight periods. A proposal for a global intergrid system aims to optimize this resource.

In recent years, the dwindling availability of non-renewable resources has emphasized the importance of cost-efficiency in solar energy devices. Technological advancements over the past decade have made solar energy more affordable, with ongoing improvements in both cost and application expected. The Earth receives about 1366 watts of solar energy per square meter, making it a nearly limitless and free resource.

A key advantage of solar energy over conventional power sources is its ability to convert sunlight directly into electricity through photovoltaic (PV) cells. Extensive research has been focused on improving the efficiency of solar cells, panels, and modules. Solar energy, being free and widely accessible, is also more abundant compared to fossil fuels, whose costs have increased over the past decade. Additionally, solar energy systems typically require less manpower and have lower operational costs compared to traditional energy production methods.

Solar energy includes the heat and radiation from the sun and can be harnessed through various technologies, such as solar thermal energy, solar architecture, solar heating, molten salt power plants, and artificial photosynthesis. Although 30% of solar radiation is reflected back into space, the remaining energy absorbed by oceans, clouds, and landmasses holds significant potential for electricity generation.

Due to its low construction and operational costs, solar energy is growing rapidly. Its applications range from industrial uses to residential purposes, like solar water heaters and solar power systems. The increasing affordability and versatility of solar energy indicate a promising future for this renewable resource.

India and world scenario for solar energy

Solar energy is rapidly expanding worldwide. In 2022, solar PV generation increased by a record 270 TWh (up 26%), reaching nearly 1,300 TWh. This marked the largest absolute growth among all renewable technologies, surpassing wind energy for the first time in history. The top ten solar energy-producing countries are China, the United States, Japan, Germany, India, Italy, Australia, the United Kingdom, South Korea, and France. The global shift towards renewable energy sources is driving the growth of solar energy production.

China’s solar photovoltaic market has seen dramatic growth over the past decade, with its solar capacity rising from just 4.2 gigawatts in 2012 to over 390 gigawatts in 2022. In the United States, solar energy accounted for 15.9% of electricity generated by renewable sources in 2022, up from 13.5% in 2021.

India ranks 4th globally in Renewable Energy Installed Capacity (including Large Hydro), 4th in Wind Power capacity, and 5th in Solar Power capacity, according to the REN21 Renewables 2024 Global Status Report. At COP26, India set an ambitious target of achieving 500 GW of non-fossil fuel-based energy by 2030.

Several schemes have been developed to promote and support solar energy, such as PM KUSUM, rooftop solar schemes, solar initiatives under PM JANMAN, and PM Surya Ghar. In the 2024 budget, the government significantly invested in solar schemes, allocating ₹10,000 crore.

Importance of solar energy

- Sustainability and Renewability: Unlike finite fossil fuels, the sun is an endless energy source, making solar power a sustainable and renewable option that won’t run out in the foreseeable future.

- Reduction in Greenhouse Gas Emissions: Solar panels generate electricity without emitting greenhouse gases. Transitioning to solar energy significantly reduces our carbon footprint, helping to combat climate change.

- Economic Benefits: The cost of solar panels has significantly decreased over the years, making solar power more accessible. This enables individuals, businesses, and communities to enjoy economic benefits such as lower electricity bills, reduced maintenance costs, and participation in programs like net metering and rebates. Additionally, the solar industry has created jobs globally, boosting economies and providing employment opportunities.

- Energy Independence: Utilizing solar energy reduces reliance on foreign oil and imported fossil fuels, enhancing energy security for nations. It also allows homeowners and businesses to become less dependent on the energy grid.

Solar panel manufacturing

The first generation of solar photovoltaic modules was made from silicon with a crystalline structure, and silicon remains one of the most widely used materials in solar photovoltaic technology. There are two primary types of crystalline silicon used in solar photovoltaics: monocrystalline and multi-crystalline silicon.

- Monocrystalline Silicon: Known for its higher efficiency compared to multi-crystalline silicon, monocrystalline silicon is used in applications where maximizing efficiency is crucial.

- Multi-crystalline Silicon: Although less efficient than monocrystalline silicon, multi-crystalline silicon is less expensive, making it a popular choice for manufacturers of low-cost solar energy systems.

Amorphous silicon, a non-crystalline allotropic form of silicon, has been widely used in solar photovoltaics, particularly in thin-film technology. While it is the most commonly used thin-film material, it is prone to degradation. Various types of amorphous silicon include amorphous silicon carbide, amorphous silicon germanium, microcrystalline silicon, and amorphous silicon nitride.

Cadmium and tellurium are also used in developing solar photovoltaics. When mixed in a specific ratio, they form cadmium telluride solar cells, which are considered the most effective thin-film material due to their ideal bandgap of 1.45 eV and longer stability.

While solar energy has significant advantages, a major emerging concern is the afterlife of solar PV modules. These modules are primarily made of silicon, an abundant material, and contain other metals like silver and aluminum that can be extracted for reuse. However, they also contain toxic elements like lead, which can pollute the environment if not properly disposed of.

This is where Life Cycle Assessment (LCA) becomes important. LCA measures the environmental impact of a product through every phase of its life – from production to disposal or recycling.

The Five Phases of a Product Life Cycle (Cradle-to-Grave):

- Raw Material Extraction

- Manufacturing and Processing

- Transportation

- Usage and Retail

- Waste Disposal

Components of a Solar Panel:

- Solar Cell: Made of silicon, doping materials (phosphorus, boron), and silver.

- Encapsulant: Made of polymer EVA (Ethyl Vinyl Acetate) or POE (Polyolefin).

- Cover (Solar Glass): Made of sand (SiO2).

- Cell Connector/Ribbon: Copper coated with lead and tin.

- String Connector: Copper.

- Junction Box: Made of polymer (PU).

- Cables: Copper.

- Diode: Silicon.

- Frame: Aluminum or steel.

The weight percentage of various components in c-Si solar panels is as follows:

- Glass: ̴ 74%

- Aluminum frame: ̴ 10%

- Silicon: ̴ 3%

- Polymers: ̴ 6.5%

- Tin: 0.12%

- Copper: 0.6%

- Lead: <0.1%

- Silver: 0.006%

End-of-Life Concerns:

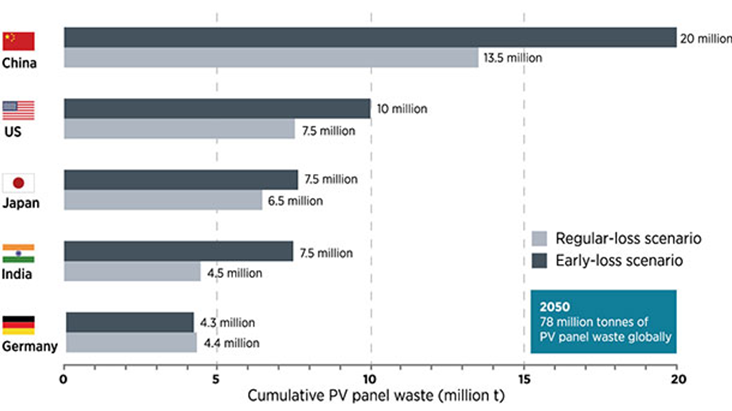

The numerous solar panel installations over the past two to three decades are beginning to show their environmental impact. Due to their limited lifespan (25–30 years), technical failures, low quality, and environmental disturbances, a significant amount of solar panel waste is emerging. Panels installed in the early 2000s are nearing the end of their life. By 2050, it is projected that there will be approximately 78 million tons of solar waste globally. This amount may increase due to the growing demand for electricity and the push for decarbonizing the energy sector with solar power.

Analysis

Solar PV module recycling process:

Image Ref: The Eco Experts

Here’s a breakdown of the typical share of component quantity that can be recycled from a solar PV module (typically Solar PV module scrap costs Rs.175~180/kg):

1. Glass: 70-80% recyclable it can be crushed and reused as glass cullet or fiberglass. This glass cullet can be sold in between Rs.8~10/kg.

2. Aluminum frames: 90-95% recyclable it can be melted and reused as raw aluminum

3. Copper: 90-95% recyclable it can be melted and reused as raw copper. Copper scrap sales around Rs.475~550/kg.

4. Silicon cells: 80-90% recyclable it can be melted and reused as raw silicon or used in other applications like ceramics

5. Rare earth metals (e.g., silver, tellurium): 50-70% recyclable it can be recovered through specialized processes and reused in new PV cells or other applications

6. Plastics (e.g., backsheet, encapsulant): 20-50% recyclable it can be recycled into lower-grade plastics or used as fuel

7. Other materials (e.g., lead, tin): 10-30% recyclable, it can be recovered through specialized processes and reused in other applications

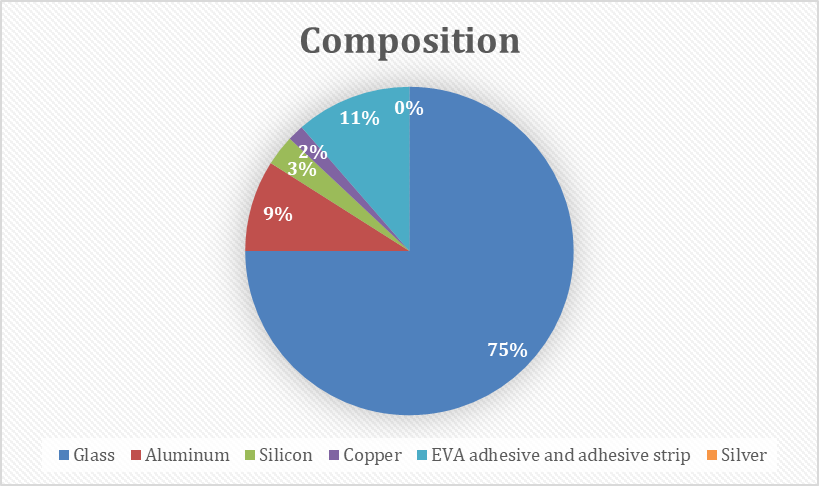

Material share:

A solar module consists of the following materials as per Industry expert: –

| Component | Percentage |

| Glass | 75.00% |

| Aluminum | 9.00% |

| Silicon | 3.00% |

| Copper | 1.60% |

| EVA adhesive and adhesive strip | 11.40% |

| Silver | 0.004% |

Interpretation

Solar PV modules have gained a lot of traction from last decade. Material or components recovered from a scrap solar PV module can be sold to the respective industries or other manufacturers. Cost of the recycled material is up to 50% cheaper from fresh material.

Heavy material like frames, glass and plastic consists most of the mass in a solar PV module. This heavy material can be processed easily and find more market fit raw material with lesser expenditure. However, materials like copper, silicon and silver involves more process due to which it cost of recovery is higher.

Among the different solar PV module technologies, crystalline Si modules represent 85–90% of the market. GWp produced by recycling of 1 ton of Si PV panels is equal to 370 kg CO2eq/kg, saving approximately 800–1200 kg CO2eq/kg in case of a module 100% manufactured from primary materials. Moreover, PV energy sources generate power with low levels of carbon emissions that cause global warming. In addition, fossil fuel-generated electricity accounts for CO2 emissions of between 400 and 1000 g CO2eq/kWh, whereas CO2 emission from silicon-based solar panels are negligible.

Source: https://www.sciencedirect.com/science/article/abs/pii/S0927024822005682

Currently China is on the top in solar PV module manufacturing and installation. However, India is also working on deep framework to enhance the renewable energy production capacity. Currently India is on the 4th position in solar PV waste generation. Solar PV modules scrap has been now been included in E-waste (Management) Rules, 2022 in India.

E-waste (Management) Rules, 2022 has laid framework by addressing manufacturers, producers and recycler. During the time of introduction of rules Solar PV modules were classified under Schedule-I which is later shifted to Schedule-II C in E-Waste Second Amendment Rules, 2023.

Key Features of Solar Panels Under the E-Waste (Management) Rules, 2022:

- Definition and Scope:

Solar panels, modules, and cells have been classified as e-waste under these rules. This means that their end-of-life disposal is now regulated, similar to other electronic products like computers, mobile phones, and batteries.

- Extended Producer Responsibility (EPR):

Producers of solar PV modules, panels, and cells are required to take responsibility for the collection and environmentally sound disposal of e-waste generated from their products. They must establish collection centers, take-back systems, or work with authorized recyclers to manage this waste.

- EPR Plans and Implementation:

Producers must submit an EPR plan to the Central Pollution Control Board (CPCB) detailing how they will collect and recycle end-of-life solar panels. The plan should include targets for collection and recycling and outline the methods used for environmentally sound management.

- Authorized Recyclers:

Only authorized recyclers, who are registered with the CPCB or State Pollution Control Board, are allowed to recycle solar panels. This ensures that recycling is done following environmental and safety standards, minimizing the release of hazardous substances.

- Record Keeping and Reporting:

Producers are required to maintain records of the quantity of solar panels produced, collected, and recycled. These records must be submitted to the CPCB annually. This data helps monitor compliance and assess the effectiveness of the e-waste management system.

- Environmental Impact:

The rules aim to mitigate the environmental impact of solar panel disposal by ensuring that hazardous materials like cadmium, lead, and silicon are properly handled. Recycling also helps recover valuable materials like glass, aluminum, and silver, promoting a circular economy.

- Compliance and Penalties:

Non-compliance with the E-Waste (Management) Rules, 2022, can lead to penalties, including fines and imprisonment. The rules empower regulatory authorities to enforce compliance strictly, ensuring that producers and recyclers meet their obligations.

Cost of machinery required for setting a 3 to 4 TPD (tons per day) plant costs around Rs.2 Cr. which can be a significant investment. In view of high adaption and near replacement approach for solar PV plants, these recycling plants soon become the prior requirement for catering the huge amount of waste.

The market for recycling solar photovoltaic (PV) modules in India is still in its nascent stage but is expected to grow significantly in the coming years as the country’s installed solar capacity continues to expand. Here are some key points regarding the market size and growth potential:

1. Current Market Size

- As of 2023, the recycling market for solar PV modules in India is small, largely due to the relatively recent adoption of solar technology in the country. Most solar panels installed in India are still within their 25-30 year lifespan, meaning the bulk of the recycling demand is expected to arise post-2030.

2. Future Growth Potential

- Installed Capacity: India’s installed solar capacity has grown rapidly, reaching over 70 GW by 2023. The government has ambitious targets to achieve 280 GW of solar capacity by 2030, which implies a substantial future volume of end-of-life panels requiring recycling.

- Estimated Waste Volume: By 2030, India is expected to generate around 200,000 tons of solar e-waste, with the figure potentially rising to over 1.8 million tons by 2050.

- Market Growth: The recycling market for solar PV modules is expected to grow as more panels reach the end of their lifecycle. The market size could expand significantly, potentially reaching billions of dollars by the 2040s, driven by regulatory requirements and the economic value of recovered materials.

3. Key Drivers of Market Growth

- Regulatory Framework: The inclusion of solar panels under India’s E-Waste (Management) Rules, 2022, will drive the establishment of recycling infrastructure and increase demand for recycling services.

- Economic Incentives: The recovery of valuable materials such as silver, aluminum, and silicon from solar panels offers economic incentives for developing a robust recycling market.

- Sustainability Goals: India’s commitment to sustainability and the circular economy will likely push the market toward developing efficient and environmentally sound recycling processes.

4. Challenges

- Lack of Infrastructure: India currently lacks sufficient infrastructure for large-scale solar panel recycling, which presents both a challenge and an opportunity for market growth.

- High Initial Costs: The establishment of recycling plants requires significant investment, which may be a barrier to immediate market expansion.

5. Opportunities

- Investment Potential: There is a significant opportunity for investment in solar PV recycling facilities, technology development, and research into efficient recycling methods.

- Job Creation: The growth of the recycling industry could lead to the creation of new jobs in manufacturing, logistics, and environmental management sectors.

Leave a Reply